The Ultimate Guide To Factory Automation

New technologies have been developing since the dawn of recorded human history. Everything is slowly changing going in line with the rapid advent of technology. It is almost like humans can’t seem to function without relying on technology. Whether it is a smartphone or any other smart home technology like wireless LED lights and robot vacuum cleaners, technology has made our life easier and faster. Not only does technology bring a strong impact on our lives, but it also plays an important role in the professional industry.

Technology has shown an extraordinarily rapid growth that brings a tremendous impact in today’s day and age. Along with the advantages of these recent developments, it was extremely likely that technology and machinery would also continue to be manufactured and enhanced in the professional industry in the future. In an effort to stand out the most among any other businesses in the industry, many businesses release something more innovative every day. Thanks to the advancement of technology, the existence of a factory automation system is here to bring a positive impact on the professional industry, especially the manufacturing industry.

What is a Factory Automation System?

The use of technologies and automation systems in the manufacturing process is what we referred to as “factory automation”, with the primary goal of raising productivity in the industry and lowering operational costs. The degree of automation might range from complete human involvement throughout every step of the manufacturing process to automation of a particular operation.

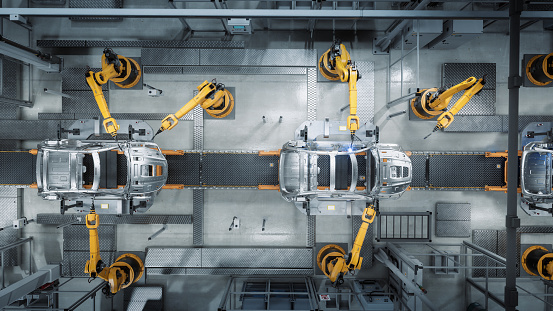

Factory automation move as automating tools that operate the whole production line through the use of microcontrollers, computers, and other control devices. The goal is to eliminate manual intervention throughout the whole manufacturing process, from order placement to actual completion of a product. As mentioned before, factory automation is important in the industry especially to boost outputs, reduced material waste, and create a better quality of a product while also reducing costs. Additionally, it is also intended to create safer working conditions and significantly reduce any possible danger associated with handling dangerous equipment for human workers.

3 Types of Factory Automation

- Single Automated

As its name suggests, this type of factory automation is the use of a machine to automate a single repeated process such as cutting packaging, inspection, cutting, welding, packing, or another single action that requires a repeating process. The components can be manually placed and inserted into the machinery. That means it’s inappropriate for any circumstances in which a user might subsequently decide to add more equipment that executes ancillary functions.

- Automated Production Lines

An automated production line is a collection of machines connected by systems called transfer and electrical control systems. In this type of factory automation, a specific product is processed in a sequence as it passes along the line in a predetermined production step, with each workstation performic a particular task. The sequence is completely laid out and the degree of operator engagement is determined by how much automation is being used. Operators are only required for supervising, monitoring, and maintaining the machinery in a fully automated production line.

- Fully Automated

A fully automated factory does not require any operators or workers, and it can still continue to function even while the light is off. Even self-adjustment and the measurement of the product quality can also be done in this type of factory automation. …